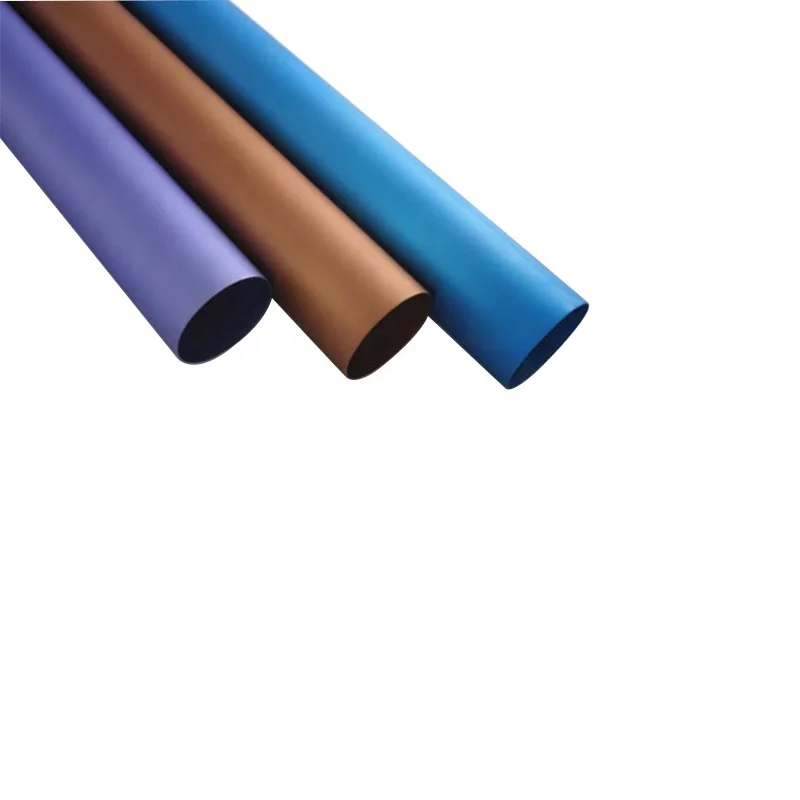

These are essentially plastic parts manufactured using the process of plastic injection. Injection Molded from propiatary components The process begins with the heating of relatively plastic resin to convert it into a molten state. The melted plastic is then injected into a mold, which essentially creates the final shape of the part. Once the plastic has melted and been left to cool, it is removed from the injection mold. And this whole process can be repeated unlimited number of times, that allows for producing a very large quantity of the same part in short amount time.

Plastic injection components used in manufacturing has lots of good points Indeed one of the huge in-hand benefits is that these components can be made very soon. This speed saves money, especially when parts are being produced in high volume. Plastic is also a light material, which makes it convenient for use and transport. And it is durable and tough so can deal with a lot of use without breaking. Manufacturers can form plastic into any part of design, thus are able to meet every need. Aside from the fact that plastic is so low-maintenance, many different types of products are produced this way.

There are a number of key factors that determine the selection of plastic injection parts. Select the Right Type of Plastic for the Application Beyond focusing on your design, you also need to pay attention that if you are designing a part from plastic- then what type of thermoplastic should be used in making it. Plastics are ideal for many applications since different ones offer unique characteristics: robust or lightweight, flexible weight saving and insulation to name a few. The type of plastic is should match with the what kind of need for this product. Furthermore, the shape and style of a die plays an essential role in this process. A good mold will make parts on a consistent basis - all to the correct size, shape each time they are produced.

There are some steps to be followed when the plastic injection components is being made with high quality. Two, is to come up with an elaborative design specification. This document clearly outlines the size, shape and even surface finish of a given component. Once a mold has been created, rigorous testing is required to verify that it complies with the dimensioned call-outs on your design document. As the parts are manufactured, quality control steps should be taken to ensure that there is no fault or variation in the produced part. This practice contributes towards identifying issues soon enough so that only good components are delivered.

There are various industries where plastic injection components can be used for different activities. Automotive — such as interior and exterior of the car (parts made from plastic) Those parts include key elements such a s the instrument panel — which houses both controls and information displays — as well as bumpers to protect cars in crashes. The manufacture of essential devices and instruments, such as the syringes that are used to inject medicines or surgical tools which aid doctors in performing necessary procedures for patients is largely reliant on plastic components within the medical field. Similarly in the electronics industry, plastic parts are used as protective casings and hulls for devices such as computers and mobile phones. All in all, One of the many different applications and benefits that plastic injection components have; which are present across a lot of different industries.

You can track the manufacturing condition of your product at any time by using our customized services Also we have plastic injection components certificates ISO certificates SGS certifications and a Reach certificate Customers can hire a professional to provide complete services This includes sketching the sketches prior to production and recording product videos after production Choose the quickest shipping option so that you can receive your product in the shortest time possible

The plastic injection components QC department is staffed with experts to inspect products every day, ensuring the quality of your products. This allows you to make a choice about factory cooperation with confidence. served more than 52 countries, 5000+customers, famous brand like Apple, Huawei, Philip, LG, Dji, Nissan and so on.

CNC Turning, CNC Milling, Metal Fabrication, Stamping, Laser Cutting, Bending, Powder Metallurgy, Cold Heading, Casting, injection molding.plastic injection components SLA/SLS/SLM

Our factory is spread over an surface of more than 4000 square meters. We employ more than 100 workers. We are a factory that has over 24 years of foreign trade and manufacturing experience.We focus on CNC machining service, plastic injection molding, sheet metal fabrication and hardware. plastic injection components service provided, RD, engineering team more than 12 people, more than 30 CNC lathing machine, more than 20 CNC milling Machine,32 plastic injection machine.