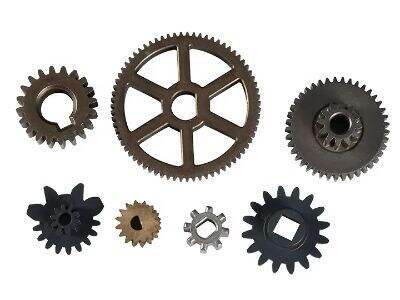

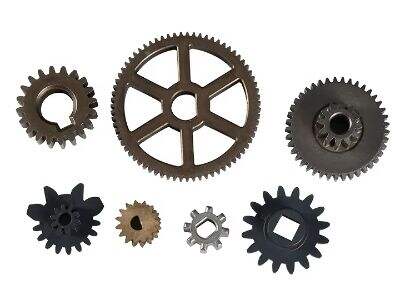

Kis helyekre fogaskerekeket készíteni nehéz lehet, de megéri! A Dakunlunnál tudjuk, hogy a kisméretű fogaskerekek is nagy szerepet játszhatnak. A fogaskerekek fontos részei számos gépnek, és szűk helyeken azokat is okosan és kompaktan kell megtervezni. Ez a cikk bemutatja, mire kell figyelni ilyen fogaskerekek tervezésekor, és hol szerezhetők be minőségi példányok projektekhez

1Fogaskerekek tervezéseMilyen szempontokat kell figyelembe venni a fogaskerekek tervezésekor szűk helyen

Néhány tényező, amelyet figyelembe kell venni fogaskerekek tervezésekor szűk helyeken. A fogaskerék mérete és alakja; 2. Gondoskodni kell arról, hogy a fogaskerék könnyedén illeszkedjen a rendelkezésre álló térbe, anélkül hogy problémát okozna. Ez azt jelenti, hogy le kell mérni a területet, és olyan fogaskerekeket kell készíteni, amelyek nem lesznek túl nagyok vagy túl kicsik. Speciális formák használata, például ferde fogazatú vagy kúpfogaskerekek alkalmazása néha némi helyet takaríthat meg, miközben a fogaskerék továbbra is megfelelően működik

A következő dolog, amit figyelembe kell venni, a fogaskerekek minősége, például milyen anyagból készültek. A legerősebbek általában acélból vagy alumíniumból készülnek, mivel nagy terhelést is elviselnek törés nélkül. A megfelelő anyag kiválasztása segíthet abban is, hogy a váltó ne legyen túlsúlyos, ami különösen fontos kis helyeken. Ha a fogaskerekek túlsúlyosak, az általában rontja a gép teljesítményét, ami korai elhasználódáshoz vezethet

Egy másik lényeges tényező a fogaskerekek fogai. A fogazat elrendezésétől függően a fogak befolyásolhatják a forgó fogaskerekek simaságát. Korlátozott térben kisebb fogak (vagy más fogalak) használata szükséges. Ez hozzájárulhat ahhoz, hogy a fogaskerekek jól kapcsolódjanak egymáshoz és csendesen működjenek, ami sok alkalmazásnál kívánatos

Végül ne feledkezzen meg a kenésről. Szűk helyeken elengedhetetlen, hogy minden zökkenőmentesen működjön. A megfelelő kenés csökkentheti a súrlódást és a kopást, így a fogaskerekek hosszabb ideig tartanak, jobban teljesítenek, még szoros helyeken is. A rendszeres karbantartás és ellenőrzések segíthetnek elkerülni a jövőbeni problémákat

Hogyan és hol találhatók minőségi egyedi fogaskerekek helyhez kötött projektekhez

Minőségi egyedi fogaskerekek beszerzése korlátozott helyű projektekhez gyakran nehézkes lehet, de jó lehetőségek állnak rendelkezésre. A Dakunlun-nál olyan egyedi igényekre szabott fogaskerekeket kínálunk, amelyek a legmagasabb színvonalat képviselik. Az első lépések egyikének számít megtalálni azokat a vállalatokat, amelyek egyedi fogaskerekeket terveznek és gyártanak. Ezek általában olyan cégek, amelyek rendelkeznek a szakértellel és felszereltséggel ahhoz, hogy olyan fogaskerekeket készítsenek, melyekre büszkék lehet

Érdemes felhasználói véleményeket és visszajelzéseket keresni. Ez segíthet megítélni a fogaskerék-gyártó minőségét és megbízhatóságát. Olyan vállalattal érdemes üzletelni, amelynek kiváló teljesítménye van abban, hogy termékeiket a megadott időben szállítsák, és szükség esetén megfelelően reagáljanak.

Vagy látogasson el kiállításokra és iparági rendezvényekre. Ezek az események továbbra is kitűnő lehetőséget nyújtanak nemcsak arra, hogy személyesen találkozzon a gyártókkal, hanem arra is, hogy termékeiket működés közben lássa. Kérdezhet kérdésekről, és megbeszélheti az egyes vállalatok képességeit. Emellett új technológiákat vagy anyagokat is találhat, amelyek hasznosak lehetnek a projektjéhez.

Az online értékesítési platformok is hasznos információkat nyújthatnak. Egyre több vállalat tesz közzé információkat egyéni fogaskerék-szolgáltatásaival kapcsolatban weboldalain, így könnyebb az opciók összehasonlítása. Mindenképpen kérjen mintákat vagy részletes referenciákat a rendelés előtt. Ez biztosítja, hogy a vásárolt fogaskerekek megfeleljenek az Ön igényeinek.

Általánosságban elmondható, hogy egyedi ipari fogaskerekek készítéséhez szűk helyre szükség van a rendelkezésre álló terek méreteinek ismeretére, valamint ezek anyagaira is; a fogazat jellemzőire és a fogak számára, továbbá arra is, hogyan fogja őket kenni. Éppen olyan fontos azonban a megfelelő gyártó megtalálása, mint például a Dakunlun. Ők ugyanis tényleg élvezetessé tudják tenni a fogaskerekekkel való kísérletezést akár közönséges kompakt térben is

Mik a fejlődési irányok az egyedi fogaskerék-tervezés terén kis helyeken

A technológia fejlődése a mai társadalomban folyamatosan halad előre, akármi is az oka; kisebb, gyorsabb és egyre praktikusabb dolgok készítéséért. Az egyik fő terület, ahol jelentős átalakítás zajlik, az a szűk helyekre szabott fogaskerekek tervezése. A Dakunlun és hasonló vállalatok új ötleteket és technológiákat alkalmaznak olyan fogaskerekek készítésére, amelyek szoros helyeken is jól elférnek, mégis kitűnően működnek. Az egyik fejlesztés a számítógéppel segített tervezési (CAD) szoftver alkalmazása. A mérnökök ezt a különleges számítógépes programot használják részletes 3D-s fogaskerékmodellek létrehozására. A CAD segítségével meg tudják vizualizálni, hogyan fogják a fogaskerekek egymáshoz illeszkedni, mielőtt még elkészítenék őket. Ez időt takarít meg, és lehetővé teszi, hogy a fogaskerekek simán működjenek szűk helyeken

Egy másik izgalmas fejlesztés az új anyagoknak köszönhető. Régebben a váltó korábban többnyire nehézfémekből készültek, amelyek sok helyet elfoglalhattak. Ma ez megváltozott, és könnyebb anyagokat, például műanyagokat és speciális ötvözeteket használnak. Ezek az anyagok erősek, ugyanakkor könnyűek, ami azt jelenti, hogy a kisméretű fogaskerekek is nagy nyomást képesek elviselni. A 3D nyomtatás szintén óriási szerepet játszik. A 3D nyomtatás lehetővé teszi a vállalatok számára, hogy fogaskerekeket állítsanak elő különféle méretekben és formákban egy éjszaka alatt, anélkül, hogy extra helyet kellene lefoglalniuk. Ezáltal testreszabott fogaskerekeket hozhatnak létre, amelyek tökéletesen illeszkednek a rendelkezésre álló kis helyre

Végül az okos technológia radikálisan megváltoztatta a fogaskerekek gyártásának módját. Ma már számos fogaskerék szenzorokat tartalmazhat a teljesítményük nyomon követéséhez. Vagyis ha valami probléma van, a rendszer azonnal jelezhet. Ez különösen fontos egy kisebb térben, ahol a javítások nehézkesek lehetnek. Mindezek az újítások összességében lehetővé teszik olyan vállalatok számára, mint például a Dakunlun, hogy olyan testreszabott fogaskerekeket készítsenek, amelyek nemcsak kisebbek, hanem hatékonyabbak és megbízhatóbbak is

Hol szerezhető be szakmai tanács egyedi fogaskerék-megoldásokhoz korlátozott térben

Amikor egyedi fogaskerekeket kell tervezni szűk helyre, néha nehéz tudni, hol is kezdjük. Szerencsére számos szakértői forrás áll rendelkezésre. A legjobb megoldás olyan vállalatok felkeresése, mint például a Dakunlun, amelyek kifejezetten egyedi fogaskerék-megoldásokat készítenek. Ők olyan mérnökök és tervezők, akik a korlátozott helyméret korlátai között dolgoznak. Az ilyen szakemberek hasznos javaslatokat adhatnak az adott specifikus igényekhez leginkább alkalmas anyagokról és konstrukciókról.

Egy másik kitűnő forrás az online fórumok és közösségek, amelyek mérnöki és tervezési témákra koncentrálnak. Ezekben a fórumokban tapasztalt tagok vesznek részt, és néhányan megosztják saját tapasztalataikat az egyedi fogaskerekek készítésével kapcsolatban. Az ilyen közösségekkel való interakció során tanulhatunk másoktól, akik már ugyanezekkel a nehézségekkel szembesültek. Kérdéseket tehetünk fel, és tanácsokat szerezhethetünk olyan emberektől, akik sikeresen terveztek fogaskerekeket kis helyre

Nagyon hasznos lehet kipróbálni, hogy kimozduljon az ember, és részt vegyen egy ilyen műhelyfoglalkozáson vagy esetleg egy konferencián. Számos szakmai szövetség rendez összejöveteleket, ahol iparági szakértők tájékoztatnak a legújabb fogaskerék-irányzatokról és technológiákról. Ezek az események kiváló lehetőséget nyújtanak arra, hogy kapcsolatokat építsen szakemberekkel, és naprakész információkat szerezzhessen a legfrissebb technikákról. Emellett más szakmabeliekkel is kapcsolatba kerülhet, ami új ötletekhez és új lehetőségekhez vezethet

Végül ne hagyja figyelmen kívül a könyveket és online forrásokat sem. Számos könyv létezik a fogaskerék-tervezésről és az alapokról, valamint elérhető olyan is, amely kis helyre szabott fogaskerekek tervezéséről szól. Az interneten lépésről lépésre haladó oktatóanyagokat vagy tanfolyamokat is találhat. Használja ezeket az anyagokat annak érdekében, hogy elmélyítse tudását a fogaskerék-tervezési projektekkel kapcsolatban

A SZABADTÉR NÉLKÜLI FOGASKEREKEK TERVEZÉSÉBŐL A LEGTÖBBET KIHOZNIA

Nagy fontosságú az hatékonyság, amikor egyedi fogaskerekeket használnak zárt terekben. Az első lépés a környezet tanulmányozása és értékelése a fogaskerék alkalmazásának szempontjából. Minél többet tudunk meg a tér pontos méretéről és paramétereiről, annál jobban képesek vagyunk olyan elrendezést tervezni, amely működik. Más szóval, fontos gondosan mérni, és alaposan megtervezni, hogy a fogaskerekek hogyan fogják egymással, illetve a gép vagy rendszer más részeivel interakcióba lépni. A Dakunlunhoz hasonló vállalatok e lépésre koncentrálnak, hogy biztosítsák: minden általuk tervezett fogaskerék zavartalanul működjön, még teljes sötétségben is

A másik kulcsfontosságú szempont a fogaskerekekben fellépő súrlódás csökkentése volt. A súrlódás különösen akadályozhatja a mozgást, és idővel elrongyolhatja az alkatrészeket. A megfelelő anyagok használata és a megfelelő kenés minimalizálhatja a súrlódást. Például a teljesítmény javulhat olyan fogaskerék-anyagok alkalmazásával, amelyek szabadabban csúsznak egymáson. Ezenkívül a fogaskerekek megfelelő tervezése – bizonyos fogazati forma és igazítás alkalmazásával – sima működést eredményezhet, ami különösen fontos, ha korlátozott a hely és minden egyes mozgás számít.

Ezenkívül érdemes átgondolni, hogy hogyan kell összeszerelni és karbantartani a fogaskerekeket. Néhány alkatrész nehézkes lehet kis helyeken, ezért segíthet, ha biztosítja, hogy az Ön váltó olyan típusú legyen, amelyet könnyű felhelyezni és eltávolítani. A moduláris tervezés, amelynél egy alkatrészt ki lehet cserélni anélkül, hogy mindent szétszedne, hatalmas idő- (és erőfeszítés-) megtakarítást jelent a karbantartás során.

Végül gondoljon arra is, hogy technológiával ellenőrizze a fogaskerekek teljesítményét. Szenzorok hozzáadásával a fogaskerekeket működés közben lehet figyelni, és értesíteni lehet a felhasználókat, ha valami nem megfelelően működik. Mindez csak azért lehetséges, mert proaktív megközelítést alkalmazunk, amely lehetővé teszi, hogy még mielőtt komoly probléma lépne fel, közbeavatkozzunk. Ezekre a módszerekre fókuszálva olyan márkák, mint a Dakunlun, jelentős költség- és energia-megtakarítást biztosíthatnak országszerte, és egyedi fogaskerékterveket vihetnek csúcsformába – akár szűk helyeken is

Tartalomjegyzék

- 1Fogaskerekek tervezéseMilyen szempontokat kell figyelembe venni a fogaskerekek tervezésekor szűk helyen

- Hogyan és hol találhatók minőségi egyedi fogaskerekek helyhez kötött projektekhez

- Mik a fejlődési irányok az egyedi fogaskerék-tervezés terén kis helyeken

- Hol szerezhető be szakmai tanács egyedi fogaskerék-megoldásokhoz korlátozott térben

- A SZABADTÉR NÉLKÜLI FOGASKEREKEK TERVEZÉSÉBŐL A LEGTÖBBET KIHOZNIA

EN

EN

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

LV

LV

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

ET

ET

HU

HU

TR

TR

FA

FA

GA

GA

BE

BE

EO

EO

MI

MI