Have you ever heard of gears? The gears, fittings which help the machines and tools to work either at a faster pace or slow are again some very significant mechanical entities. They are almost like little helpers that bind various components of a machine to operate unitedly. A worm wheel is a peculiar type of gear used in conjunction with another, known as the Dakunlun 'worm', which turns it. Together, they become a great team able to move mountains

Worm wheel gear shaped spiral has screw type. Its body is ribbed, so it has toppings like little lines or channels that loop all over its whole body. This design makes it best suited to drive the worm wheel. This is the worm wheel and it has teeth machined into it that exactly fit to each of those grooves cut on this semi soft bronze ring gear. The teeth of the worm wheel are made to lock into -- jut like a key and a lock -- the spines/grooves on this gear

This Dakunlun worm wheel is forced to turn when the screw moves, which in turn forces that gear out into place! Now the worm wheel has one particular thing that makes it unique -it can only turn in this direction. This key feature controls the speed in which things come and go. We spoke about worm junior and the worm wheel: They cooperate like those toys we had as kids where you could only move forward, never back – that's how a worm works

worm gear and worm wheel are special in that they tend to work very well with one another, for example some of the benefits include Worm gears can let things spin very slowly, but with a ton of power. It's really cool! This allows a worm gear to exert tremendous amounts of force even when the worm (or input shaft) is moving very slowly. For instance, a worm gear in car assists the engine to turn the wheels. Without worm gears, cars would not be able to move or they could go so fast that you and I simply cannot drive

And, with improving technology, the Dakunlun worm gears gear worm wheel are getting stronger and lighter. There are new materials making these gears even smoother and a newer metal like titanium is being used. Gone are the days of just steel gears, as these new materials not only serve to increase longevity but to maximise how well they work. That means that the gears can effectively perform their function for an extended period of time without any issue

Dakunlun Worm gears and bushing, like any other machine or device for that matter require periodic maintenance in order to keep performing at an optimum level. It is necessary to clean them at regular intervals, oil it and also keep checking for the problems or any issue likely to happen. It would be like a spa for your gears! Give it much love, and your toys will last longer and perform better - the same way a well-serviced toy can keep you happy for years

They are commonly used in many machine components such as Dakunlun conveyor belts, packaging machines and printing presses. However, you may be surprised to learn that they are also found in things around us! Yes, That in a clock help precisely keep time with each tick and tock. Yes, In the bicycles it gives you smooth ride while pedaling smoothly And also yes that small thing helps your toys! For example, in small toy cars or trains worm and gear can give the impression of speed and power which makes playing more fun

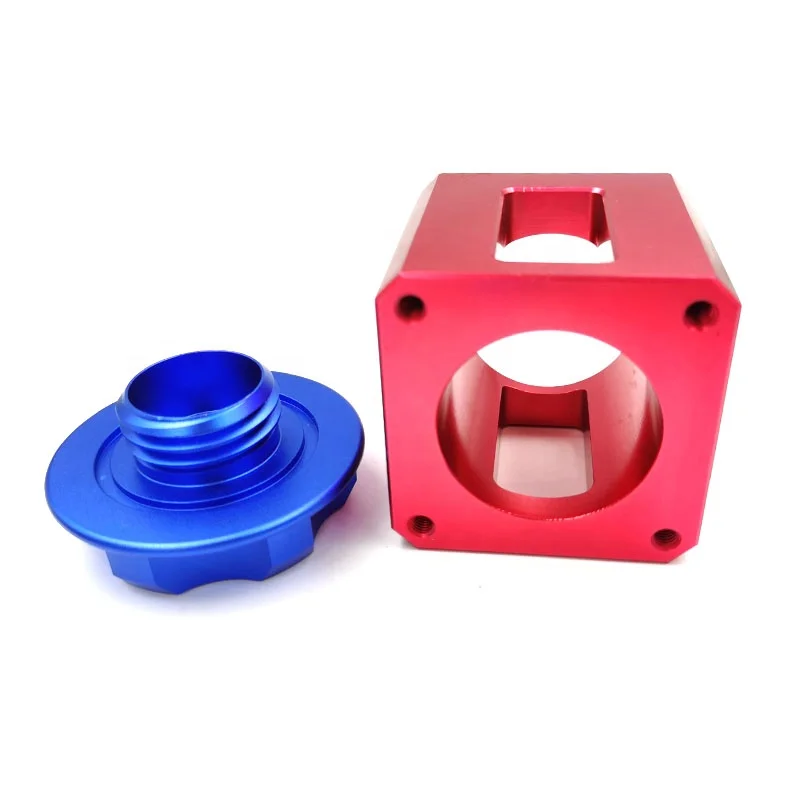

CNC Turning, Worm & worm wheel, Metal Fabrication, Stamping, Laser Cutting, Bending, Powder Metallurgy, Cold Heading, Casting, injection molding.3D printing SLA/SLS/SLM

The independent QC department is equipped with a dedicated team to examine products each Worm & worm wheel, guaranteeing the quality of your products. This allows customers to choose factory collaboration with confidence. served more than 52 countries, 5000+customers, famous brand like Apple, Huawei, Philip, LG, Dji, Nissan and so on.

The factory has an surface of more than 4000 square meters. We employ more than 100 workers. We are factory with more than 24 years of foreign trade and manufacturing experience.We focus on CNC machining service, Worm & worm wheel, sheet metal fabrication and hardware. OEM/ODM service provided, RD, engineering team more than 12 people, more than 30 CNC lathing machine, more than 20 CNC milling Machine,32 plastic injection machine.

Worm & worm wheel are designed independently to your products allowing you to track production progress at any time Additionally we offer ROHS certificates ISO certificates SGS certifications and a Reach certificate Each customer will arrange for experts to offer extensive services drawing drawings before production and recording videos of the product after it is produced so that you understand the process of production Select the most efficient shipping method so that you receive your product within the shortest amount of time